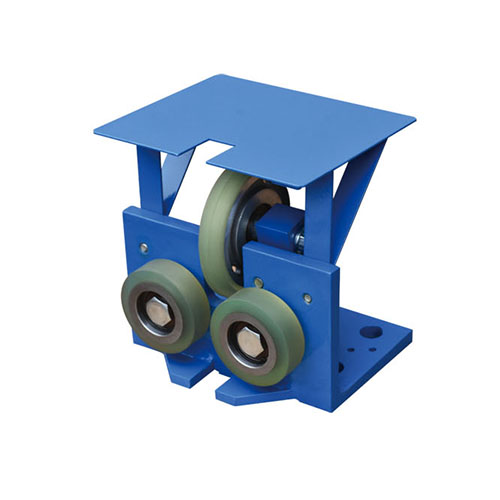

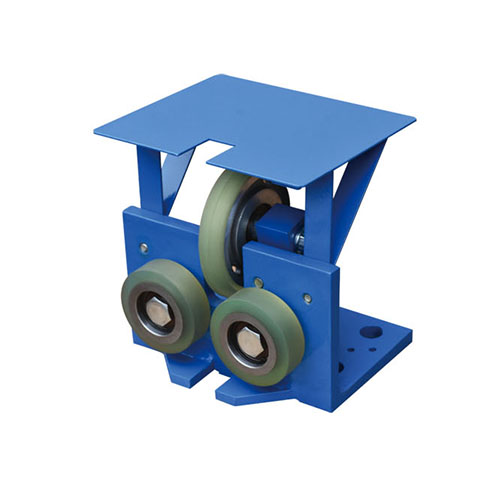

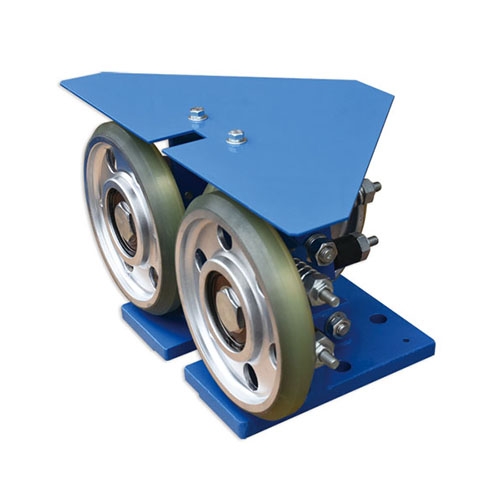

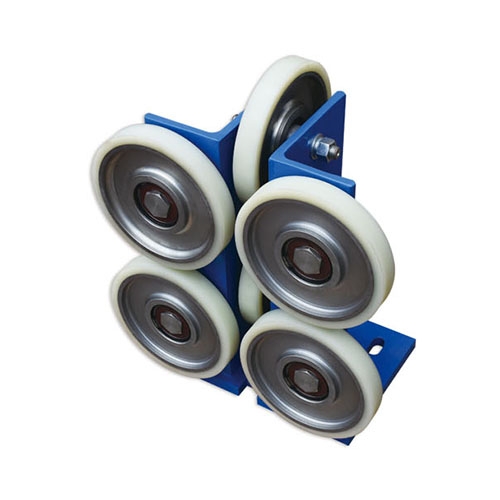

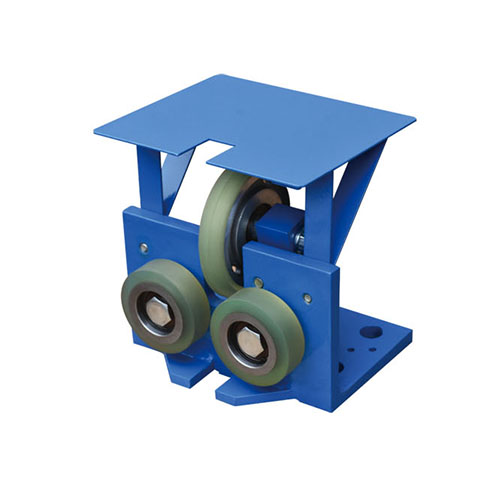

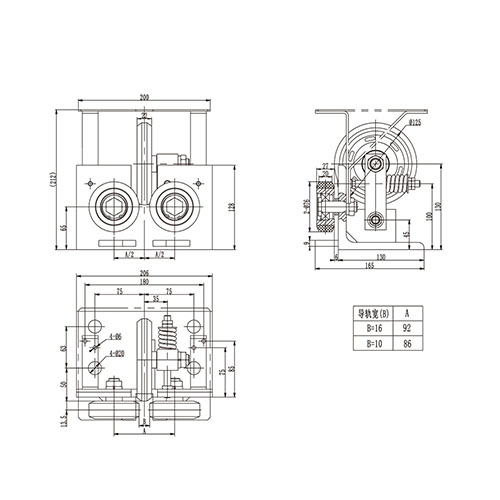

Rolling guide shoe FN-GDX-015

● Installation and commissioning of rolling guide shoes

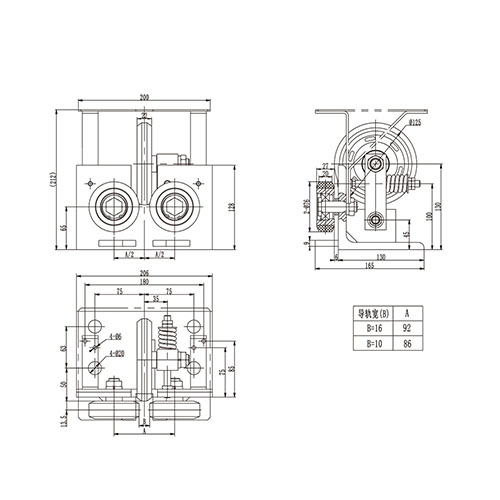

When installing, according to the illustration in the installation and commissioning instructions, select the mounting hole on the bottom plate of the guide shoe, connect with the beam body or transition plate with the appropriate hexagon bolt (with elastic pad, flat pad), and use the conversion plate (support) in the lower part of the car. ) as a connection transition.

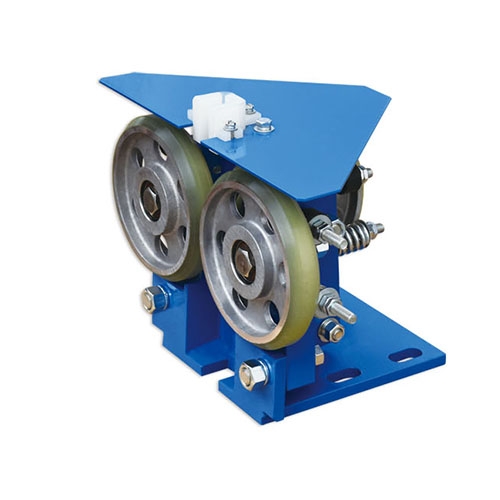

During installation, the center of the upper and lower guide shoes and the center of the safety gear are required to be on the same vertical line. The roller guide shoe should be installed in a straight position, and the guide rail is located in the center of the roller guide shoe guide. Adjust the nut above the screw on both sides of the roller to compress the spring. After the rollers on both sides are pressed against the guide rail, the pressure of the two-wheel spring should be the same. The middle roller is tightly attached to the guide rail. The center of the wheel is aligned with the center of the guide rail, and then the compression spring is adjusted.

During the installation process, the maximum pressure of the guide shoe roller when the spring is not compressed shall not exceed 25kg. If the roller pressure is too large to adjust, the car should be statically balanced and balanced.

● Use of roller guide shoes

No oil is allowed on the surface of the guide rail to prevent the roller from slipping;

The surface material of the roller is polyurethane or rubber, and the service life under normal use is 3 years;

The rolling guide shoe has a warranty period of two years (since the product is shipped from the factory). In the course of use, the wear of the roller rubber layer should be checked frequently. Uneven surface wear may occur, and the pivot may be worn. In addition, check the spring for signs of breakage. If the above situation is found, it should be replaced in time.